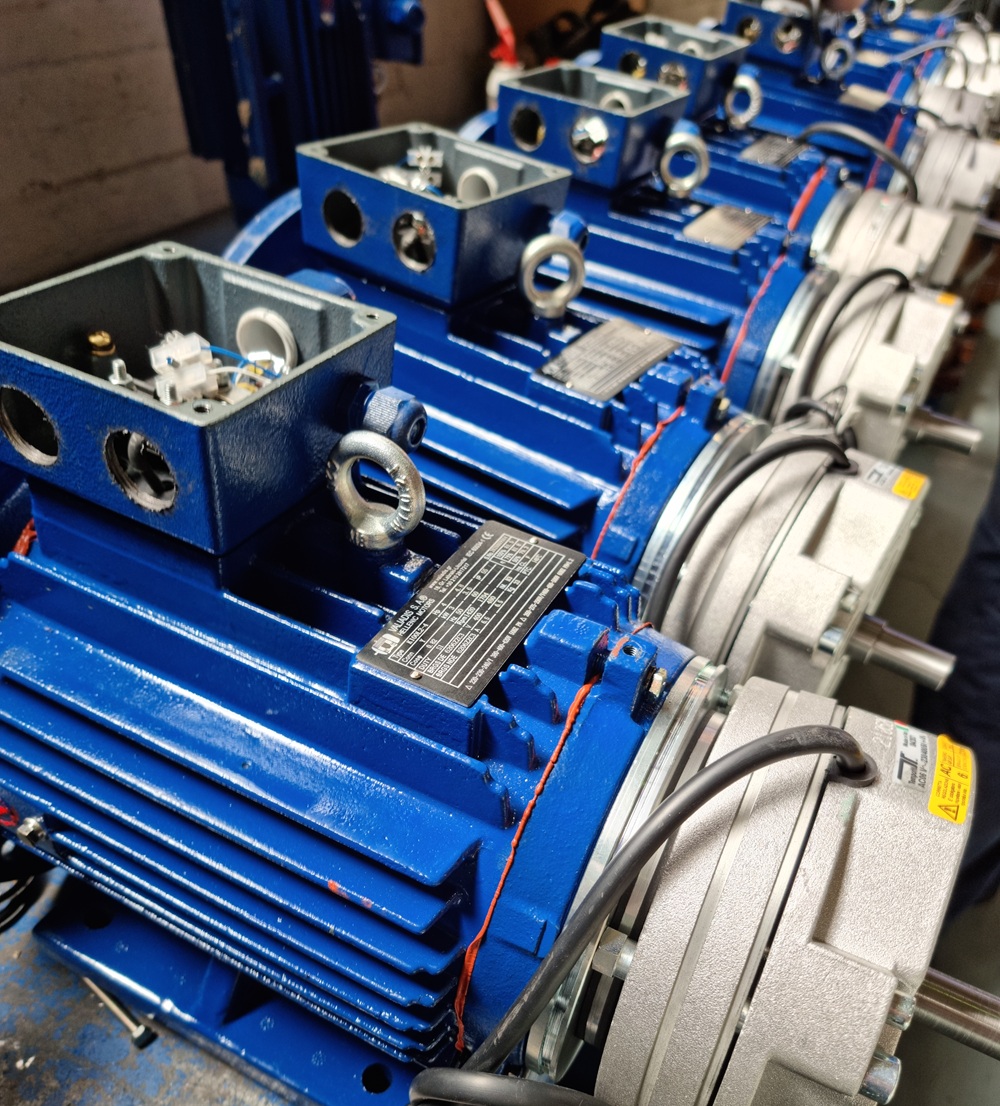

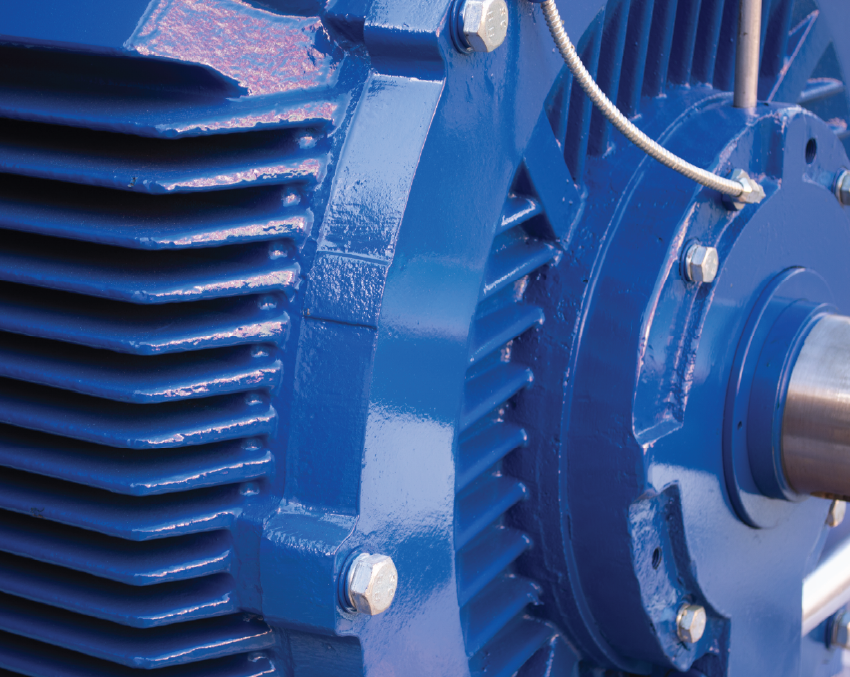

ΚΔ Series

TECHNICAL DATA

IEC 132-450 380-420 / 50Hz

IEC Motors – Frame Sizes 132 to 450

Voltage and Frequency

- 380–420 V, 50 Hz

Main Applications

- Pumps

- Blowers

- Conveyors

- Compressors

- Gearboxes

- Marble factories

- Steel industry

Standard Features

- Heavy-duty cast iron housing, with feet integral to the casing for added robustness

- Protection degree: IP55

- Slip ring and brush compartment isolated from stator and rotor, located behind the non-drive end (NDE) bearing

- Insulation class F, with temperature rise limited to 80°C

- Standard PTC thermistors in windings (one per phase, series connected)

- Oil seals on both drive end (DE) and non-drive end (NDE)

- Top-mounted terminal box, rotatable 180° for flexible installation

- Premium bearings: SKF or NSK

- Regreasable bearings for extended service life

- Standard color: RAL 5010 (Blue)

Optional Features

- Special voltages and frequencies available on request

- Insulation class H for higher thermal tolerance

- Higher protection degrees: IP56 / IP65

- Terminal box positioning: right- or left-hand side

- PT100 sensors in windings and/or bearings for advanced thermal monitoring

- Reduced frame motors (non-IEC) for compact applications

- Anti-condensation heaters to prevent moisture buildup

- Roller bearings on drive end for high radial loads

- Epoxy resin encapsulated terminal box for harsh environments

- Epoxy resin encapsulated windings for superior insulation

- Silicone encapsulated terminal box for enhanced protection

- Custom cable executions, either via terminal box or direct cable connection