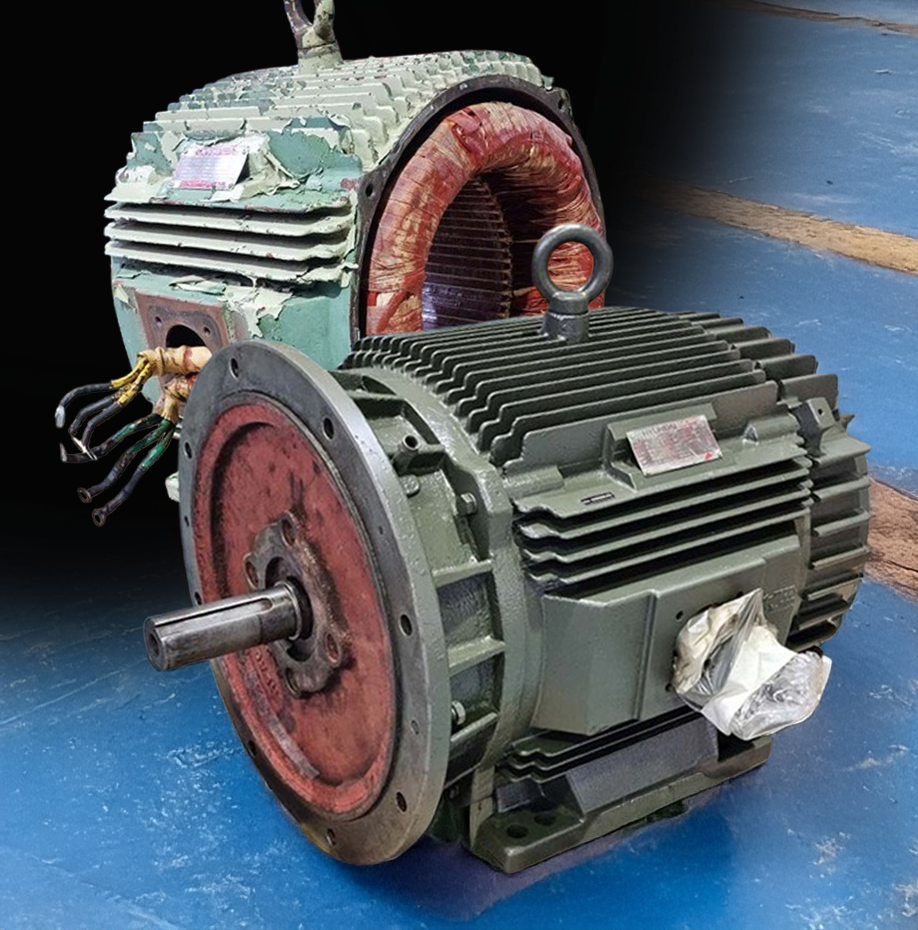

Before & After

Before & After: Electric Motor Maintenance

Workshop Feature

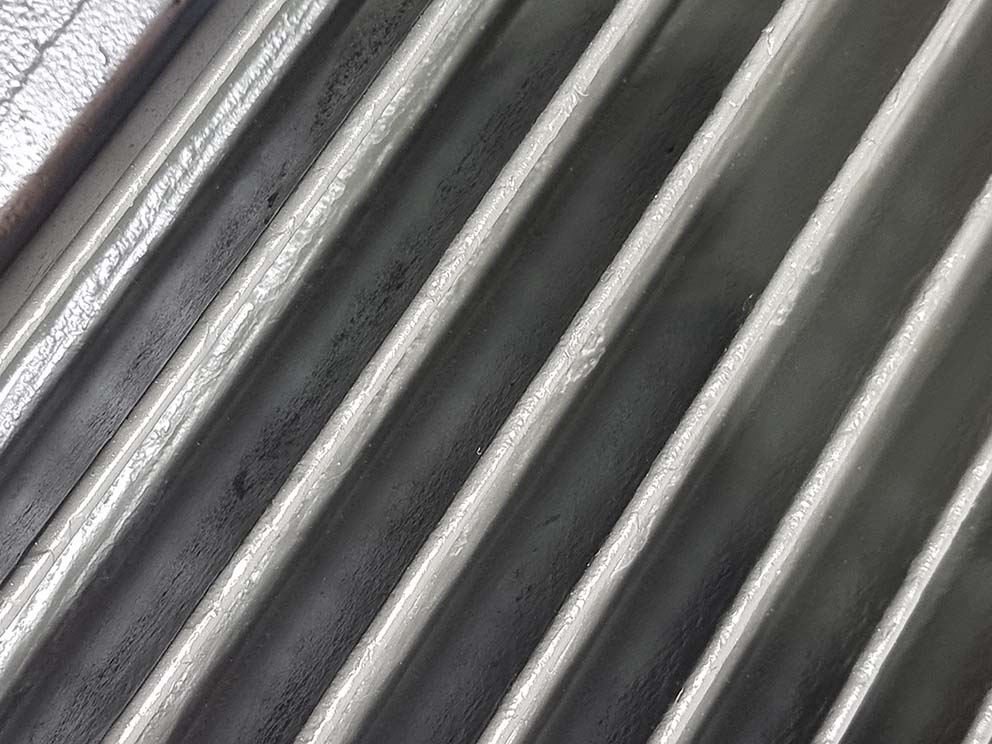

At Valiadis S.A., we continually invest in technologies that enhance the quality and precision of our work. One of the most effective tools we’ve added to our workshop is ultrasonic cleaning—a process that uses high-frequency sound waves to generate microscopic bubbles in a cleaning solution. When these bubbles collapse, they dislodge dirt, grease, and residues from even the most intricate surfaces, without damaging the underlying material.

This advanced method is now fully integrated into our daily maintenance and refurbishment workflow, ensuring that each component is treated with maximum care and technical efficiency.

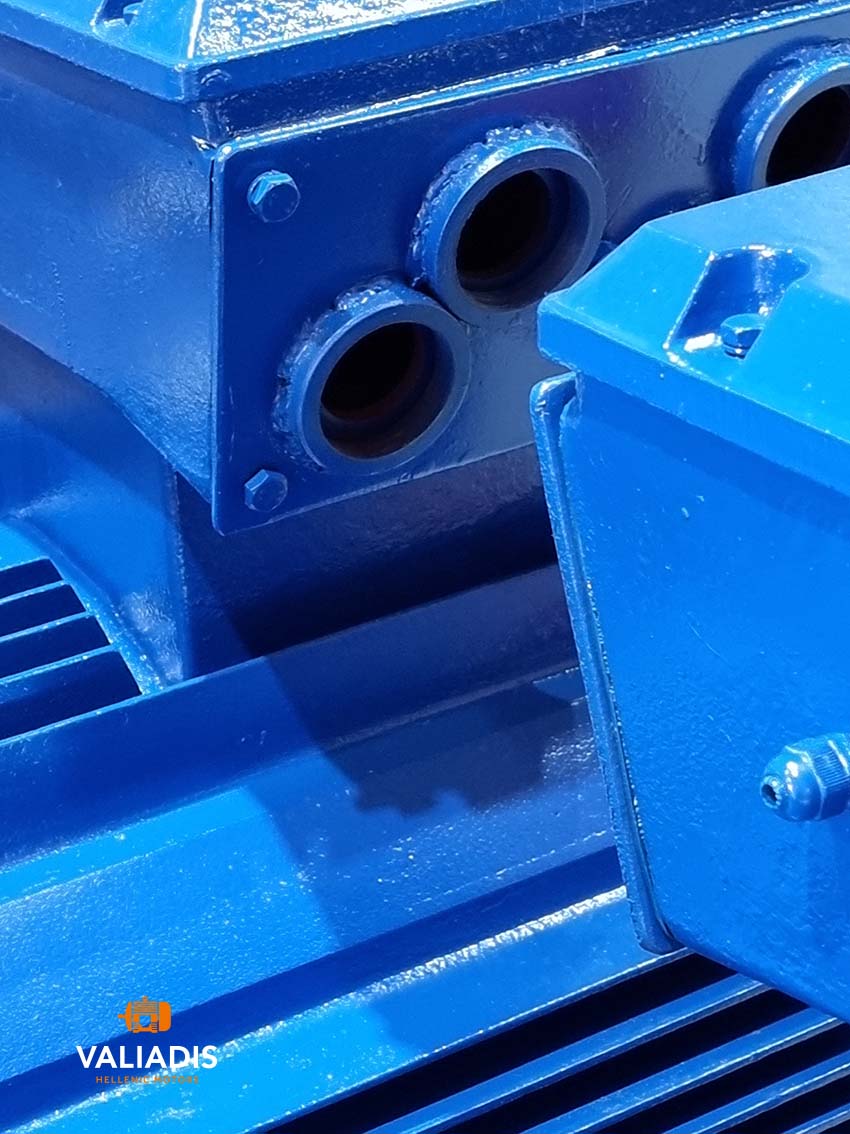

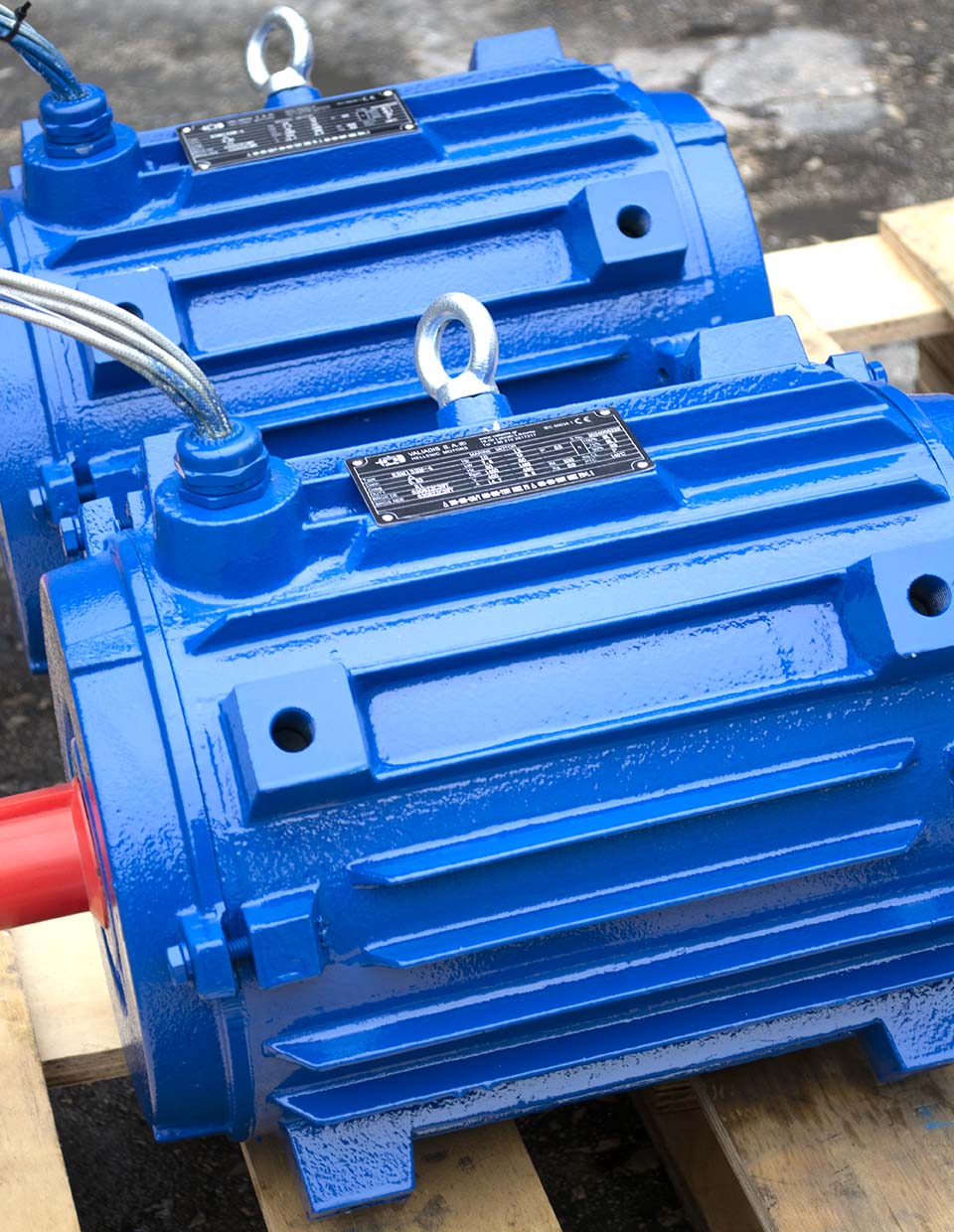

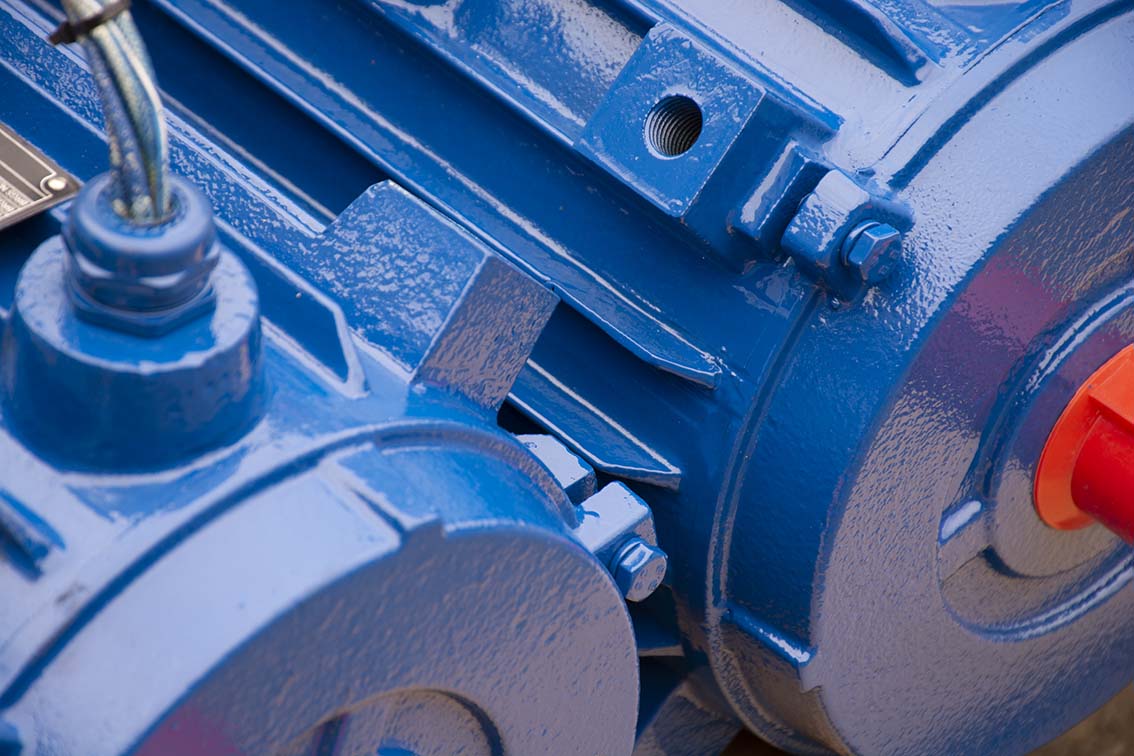

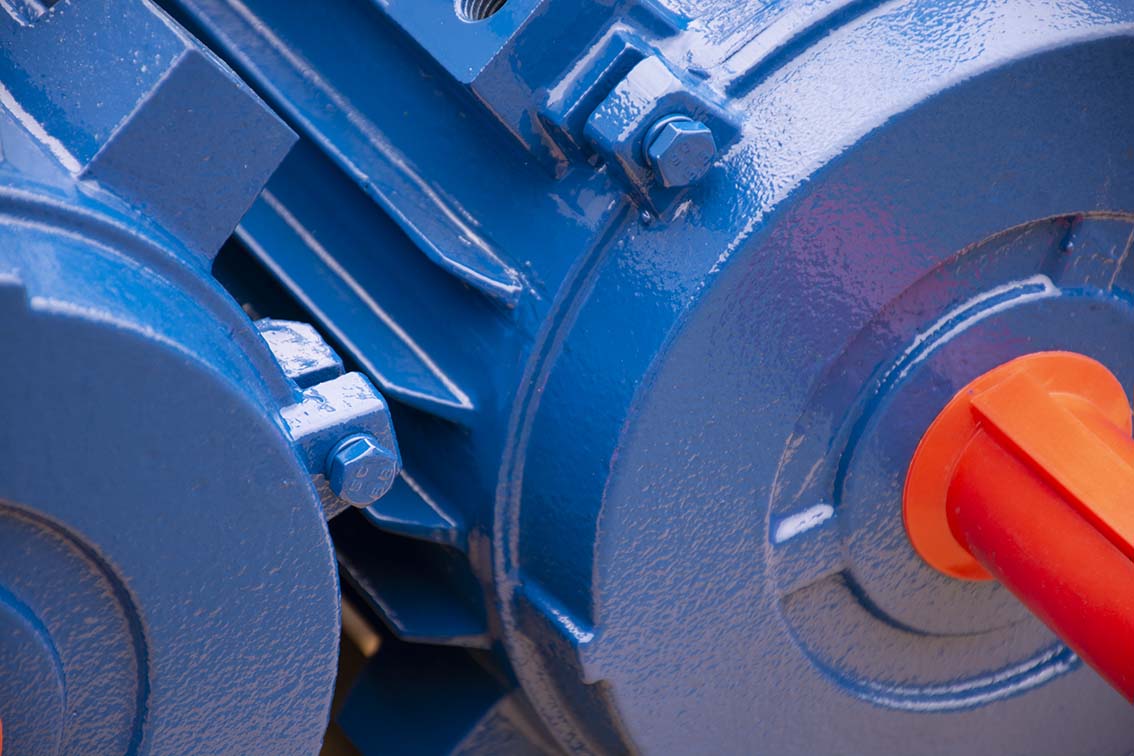

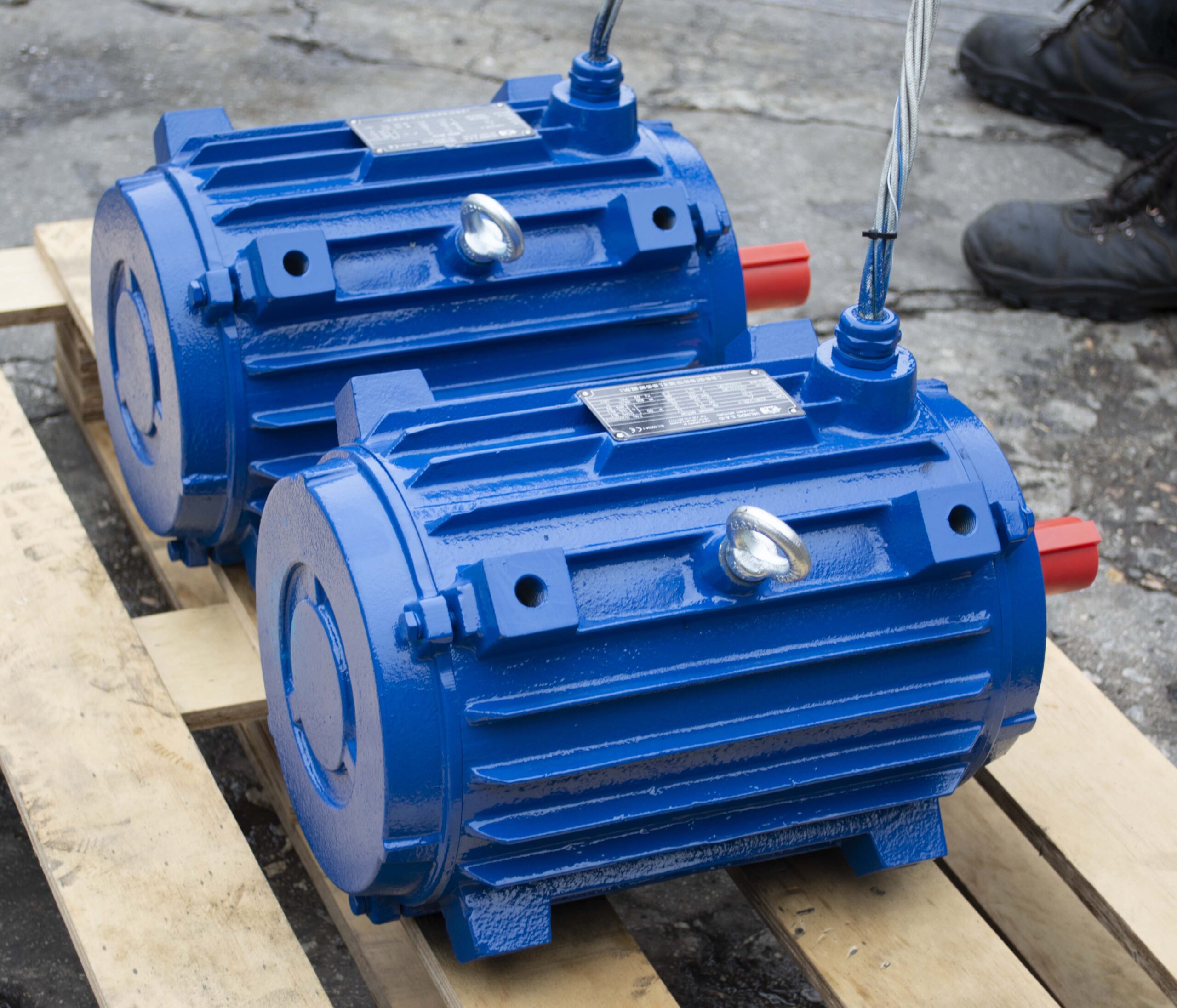

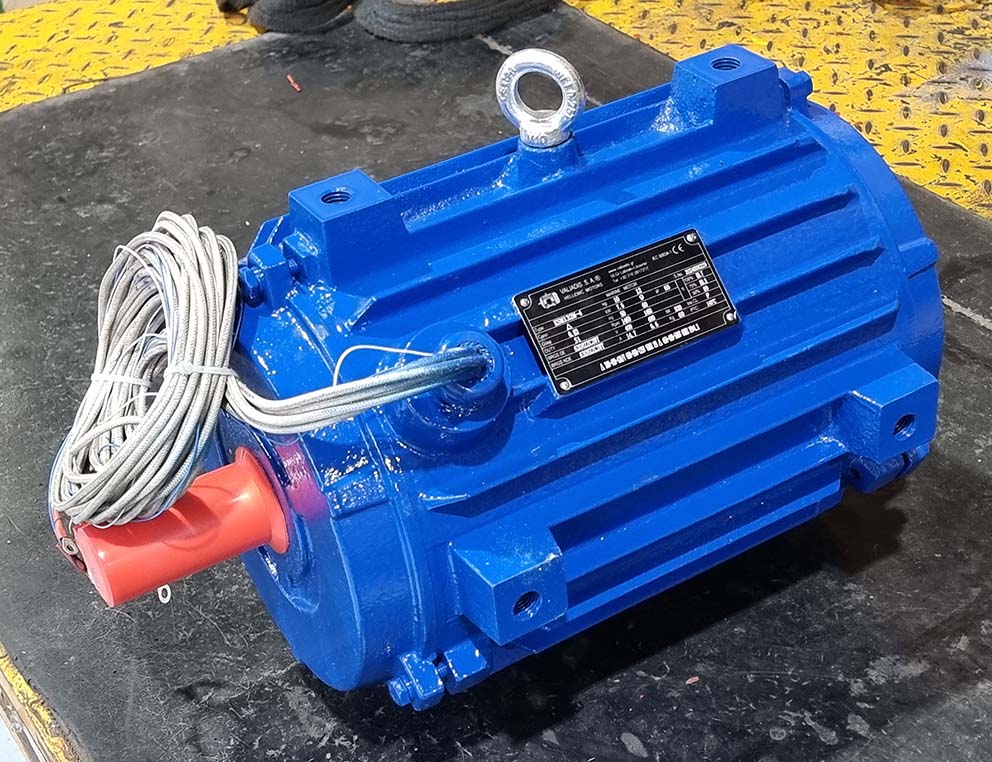

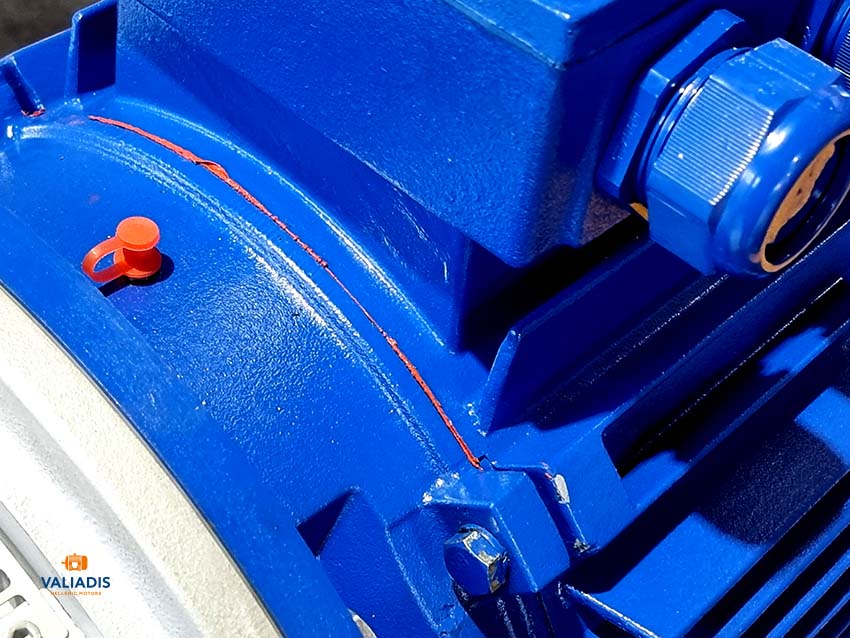

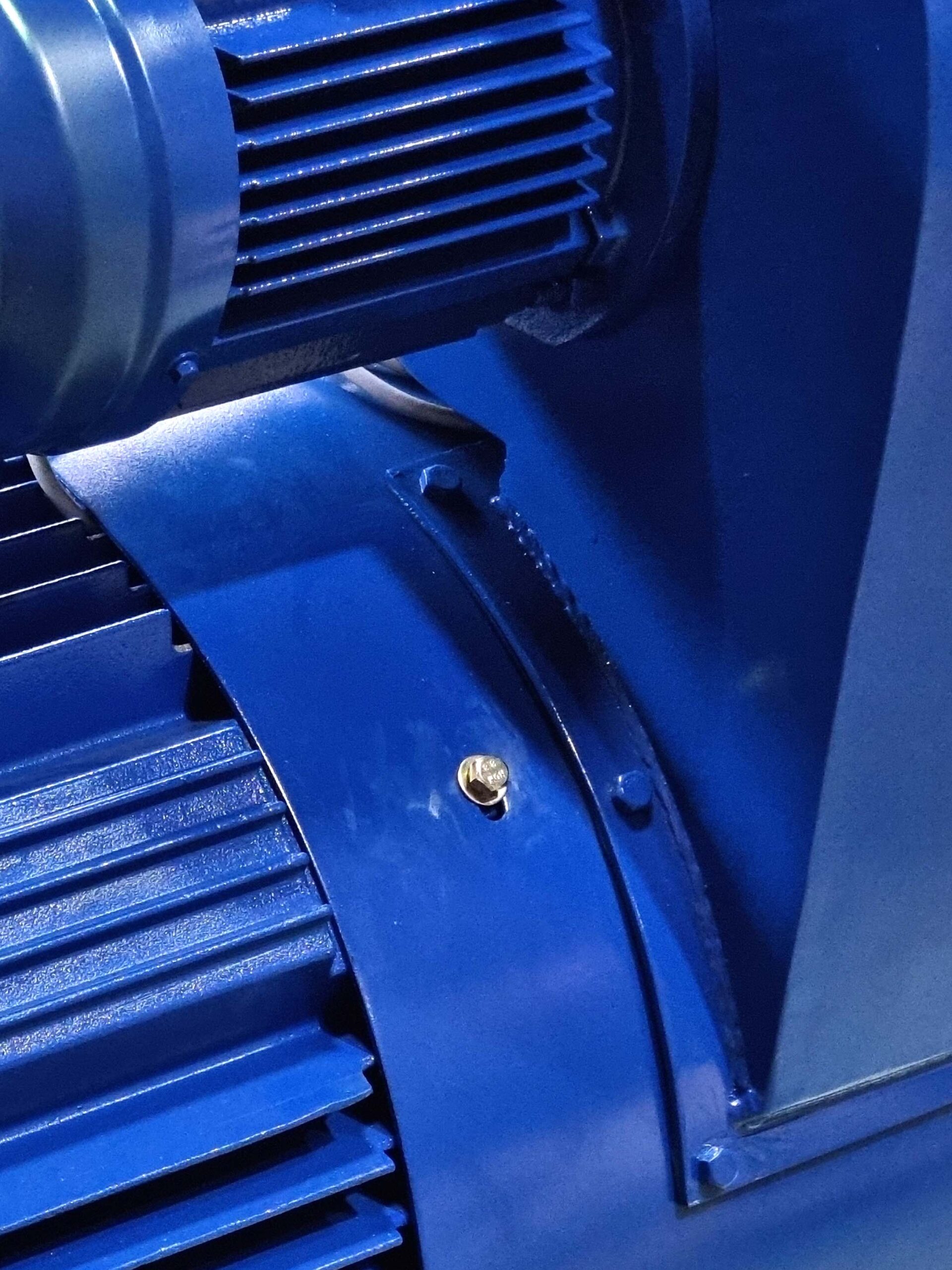

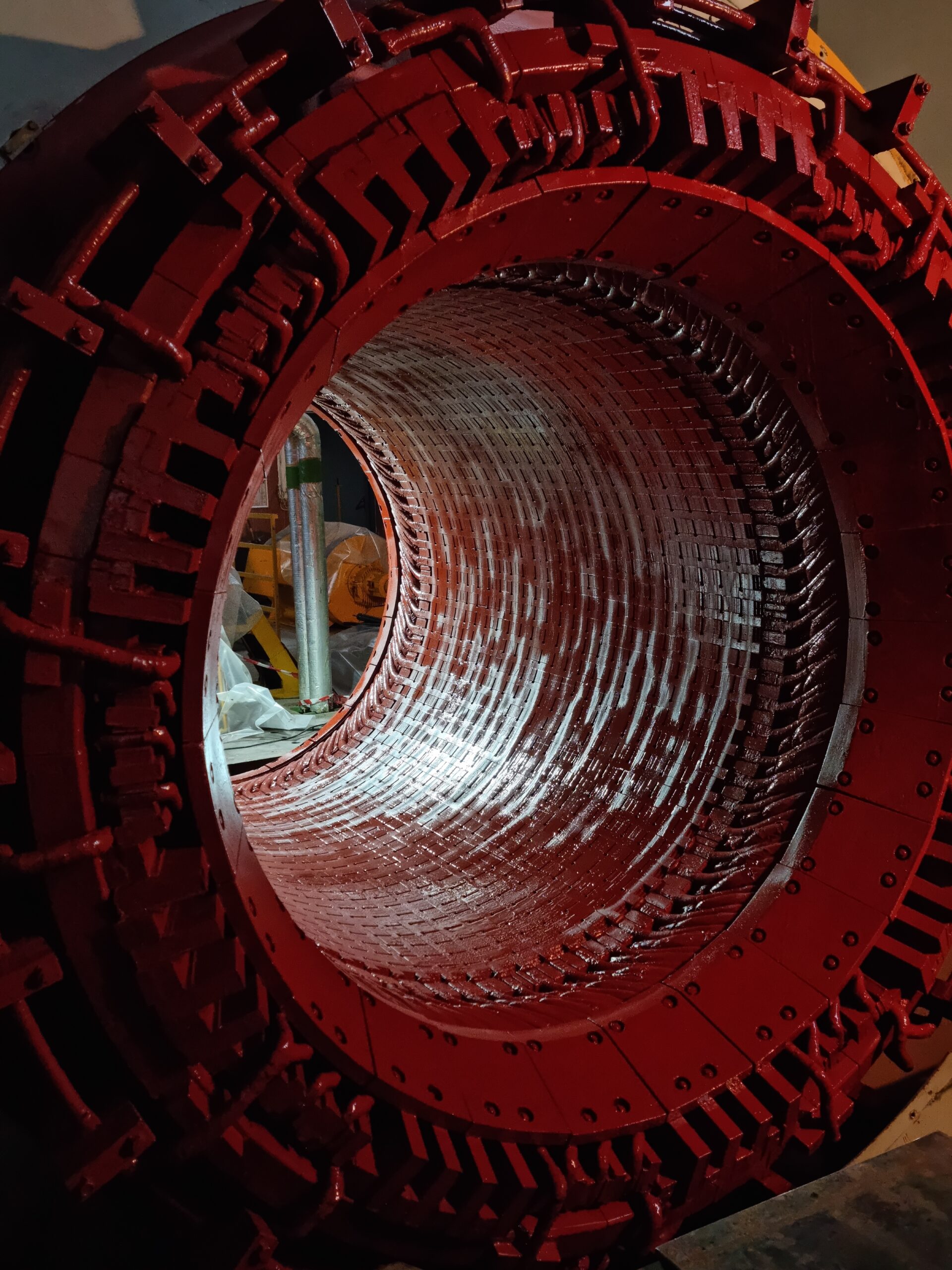

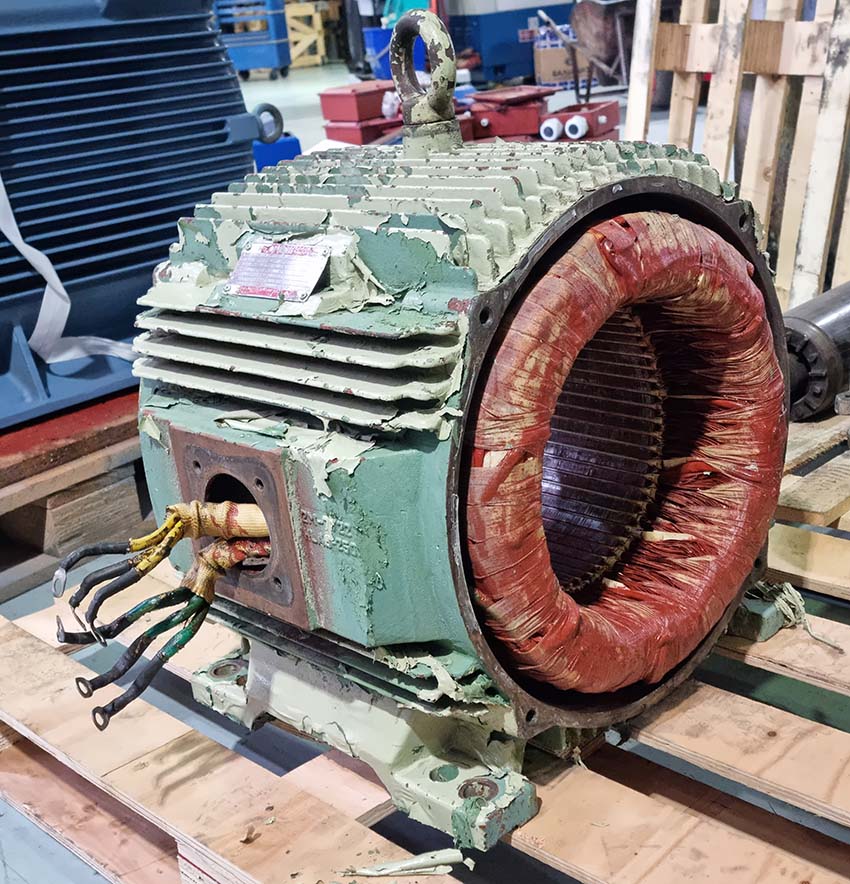

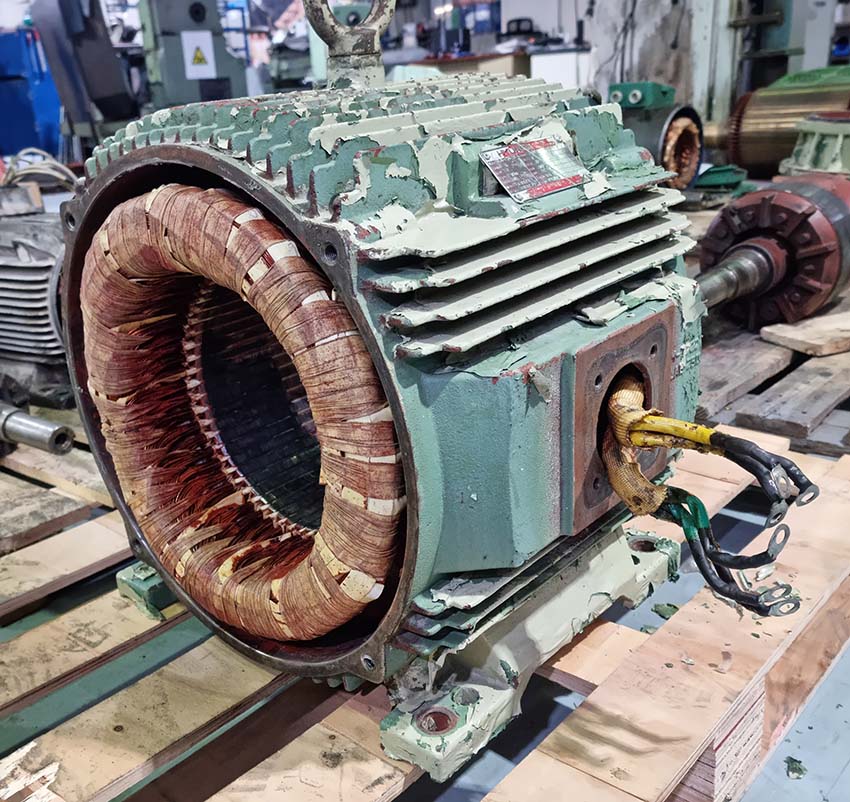

The images shown here demonstrate a recent example involving a low-voltage electric motor:

-

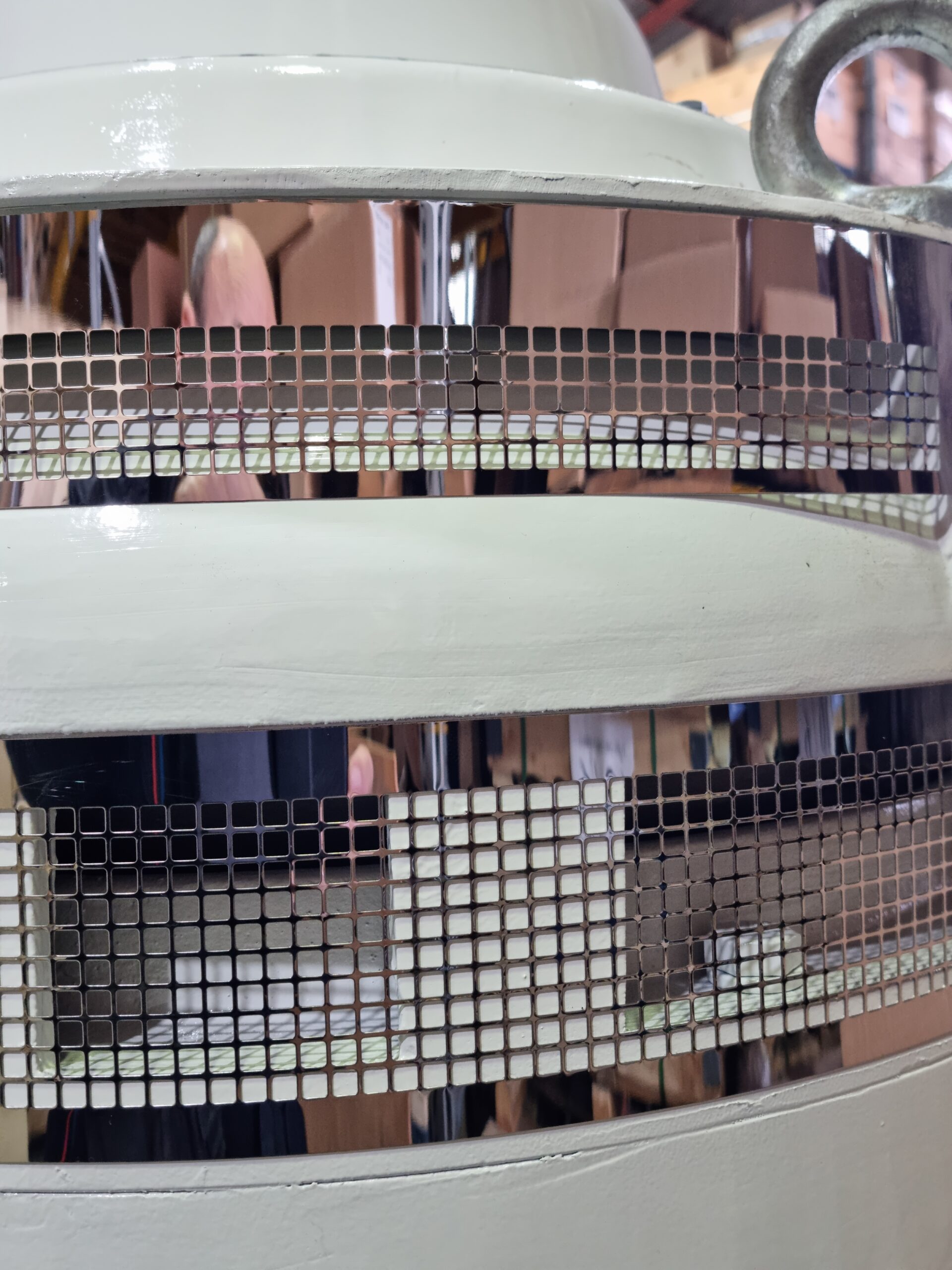

Background: The motor immediately after undergoing ultrasonic cleaning.

-

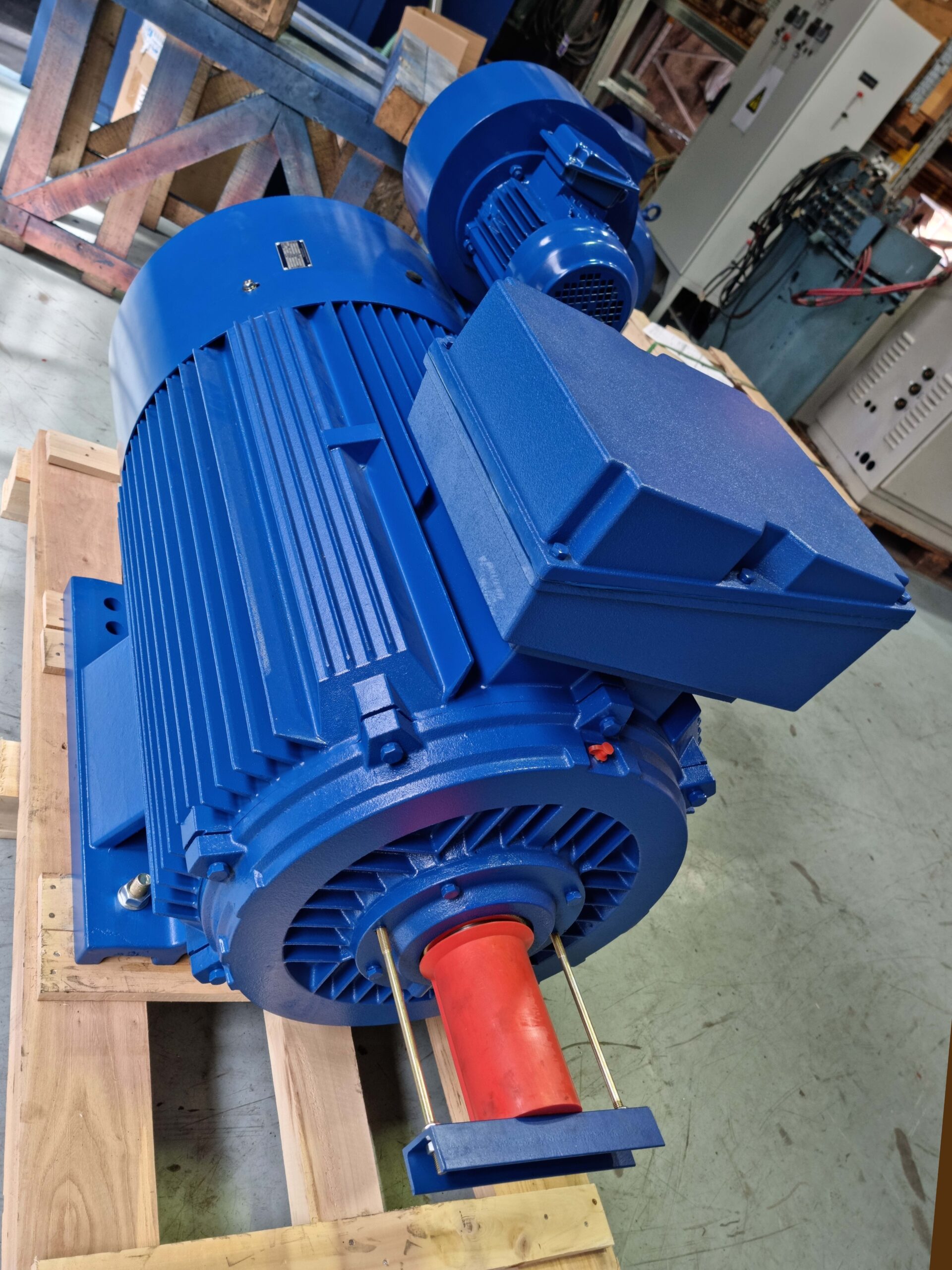

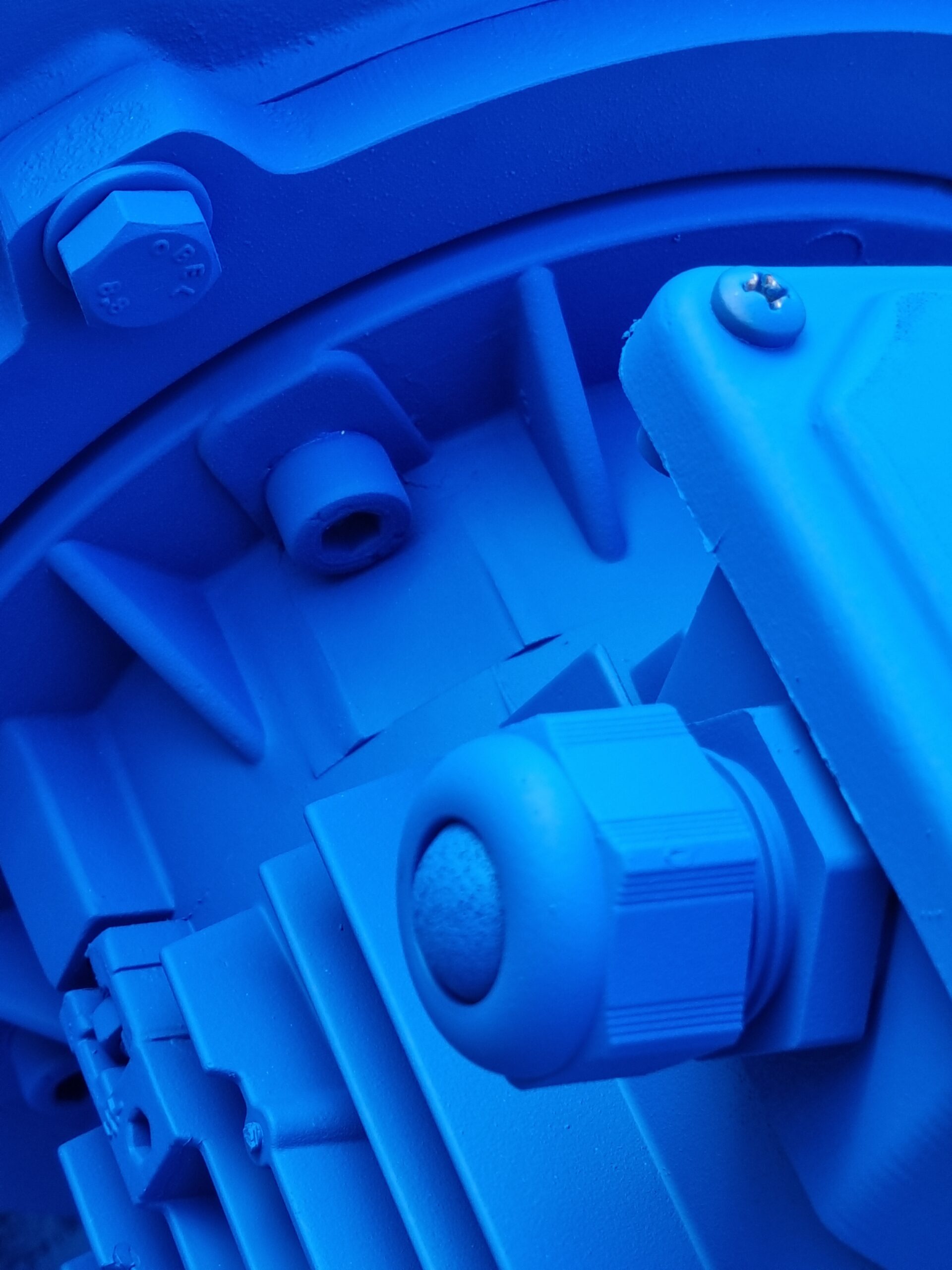

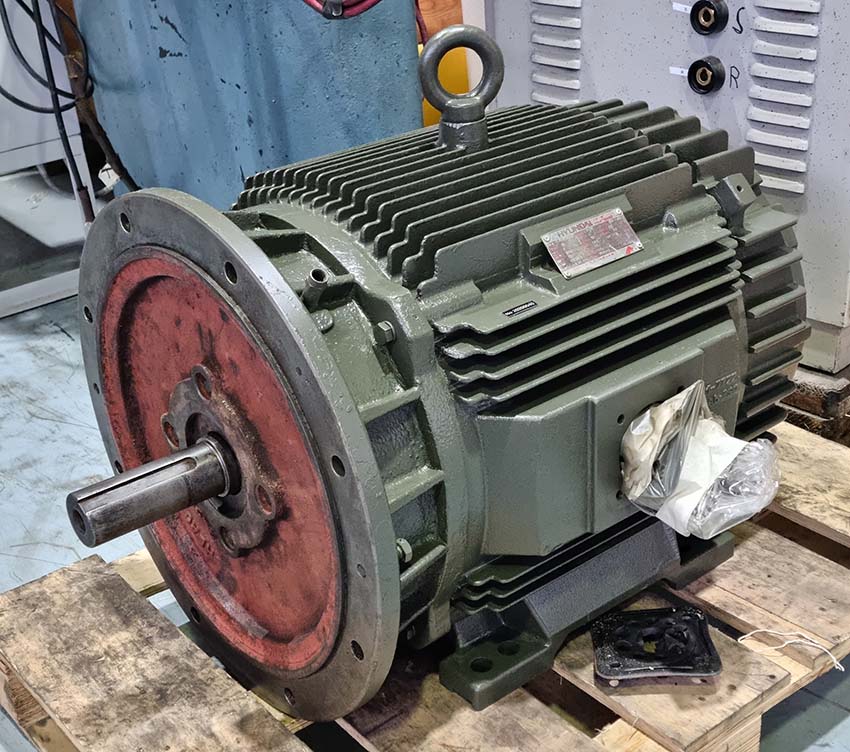

Foreground: The same motor, fully refurbished and ready for delivery.

At Valiadis S.A., we go beyond standard repair. Our approach blends engineering precision with attention to detail, so that every motor we return is not only functional, but also clean, reliable, and ready to perform at its best.

-

synthesis-4-floor2

-

20250305_140049-2

-

20250305_135939-2

-

20250305_140059-2

-

20250305_140021-2

-

20250228_153117-2-s

-

20250220_132836-2-s

-

20250220_132819-2-s