K-PMDC Series

DC

MOTORS

DC

MOTORS

TECHNICAL DATA

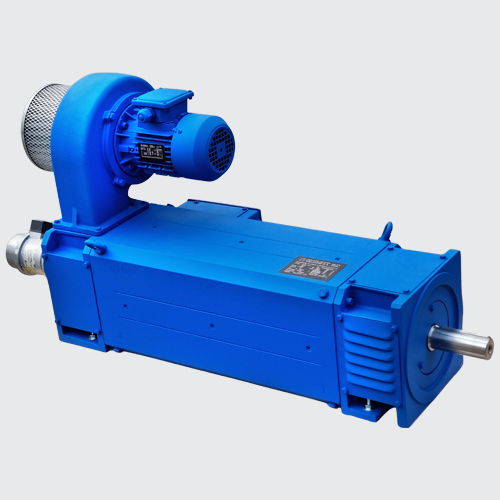

K-PMDC Series — Permanent Magnet DC Motors

High-performance brushed DC motors for demanding applications.

The K-PMDC Series offers a versatile range of brushed permanent magnet DC motors (12V – 48V, 0.25 to 4.00 HP) built with high-energy Neodymium (NdFeB) magnets for superior power density, excellent commutation, and long brush life. Compact yet robust, these motors are ideal for industrial, automation, and mobility solutions where reliable and efficient performance matters.

Key Features:

-

Voltage Range: 12V to 48V

-

Power Output: 0.25 kW to 3.00 kW

-

Compact Design & High Power Density

-

Mounting Options: Foot-mounted or flange-mounted

-

Connection Types: Terminal box or screw terminals

-

Cooling Type: IC 410 / IC 411 natural air cooling

-

Protection Class: IP44

-

Duty Cycle: S2 intermittent operation

-

High Efficiency: Up to 83.1%

Applications:

-

Electric vehicles and carts

-

Conveyors and transport systems

-

Lifting devices and winches

-

Robotics and automation

-

Pumps, fans, and portable equipment

Models Overview:

M.06.03 & M.06.06 Series

Power range: 0.25 – 0.90 kW

Voltage: 12V & 24V

Speed range: 700 – 4000 rpm

Weight: ~7–8 kg

M.10.09 & M.10.11 Series

Power range: 1.10 – 3.00 kW

Voltage: 12V, 24V & 48V

Speed range: 1000 – 2800 rpm

Designed for higher torque and extended performance