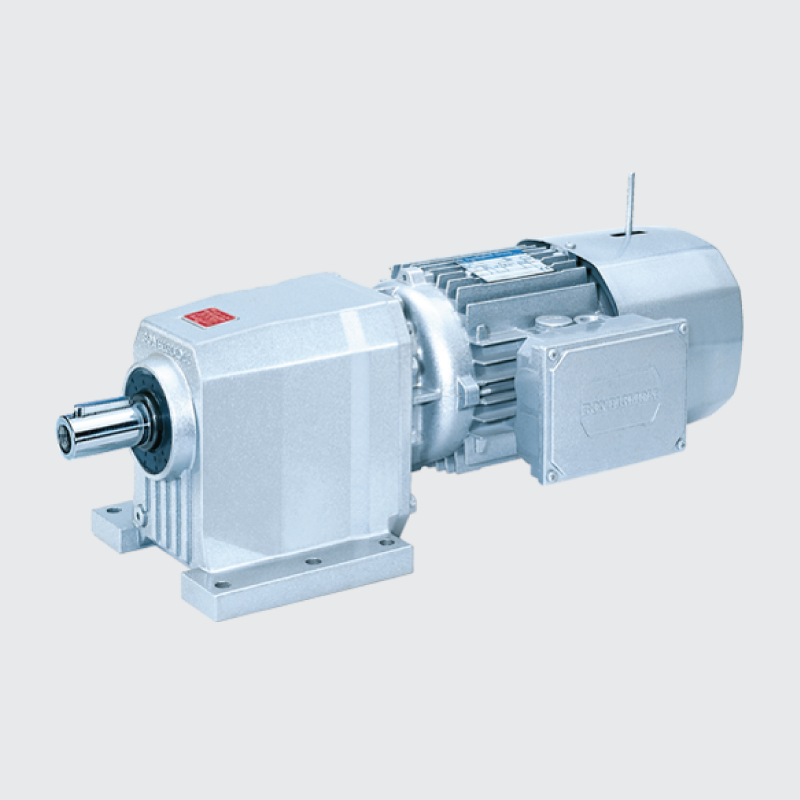

MKC Series

TECHNICAL DATA

Single-Phase IEC Motors – Frame Sizes IEC 56 to IEC 100

Poles: 2, 4, 6

Voltage Range: 220–230 V, 50 Hz

Main Applications

-

Ventilation and Airflow Systems

-

Pumping Installations

-

Machinery in Food and Light Industry

Standard Features

-

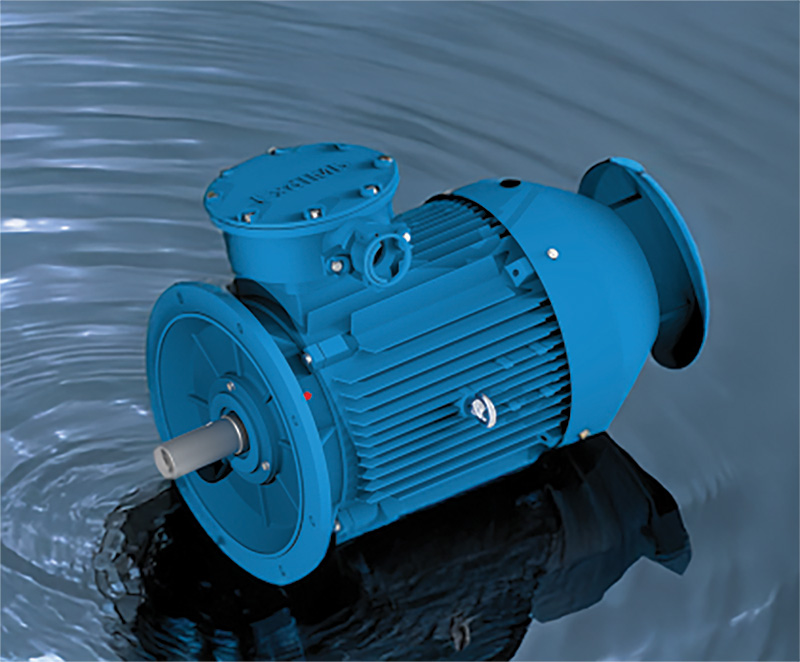

Lightweight, industrial-grade aluminium housing for corrosion resistance and ease of handling

-

Permanent capacitor run design for smooth, reliable performance

-

IP55 protection against dust and water

-

Insulation class F, with temperature rise limited to 80°C

-

Terminal box rotatable by 180° for flexible cable routing

-

SKF or NSK bearings for long-lasting operation

-

Standard color: RAL 5010 (Blue)

-

Removable feet, allowing terminal box repositioning on either side for installation flexibility

-

Cast iron endshields for frame sizes 80–132, enhancing structural strength and vibration resistance

Optional Features

-

Electronic start capacitors for high starting torque applications

-

Special voltages and frequencies available on request (e.g., 110V / 50Hz)

-

Compatible brake kits for all motor sizes

-

Custom cables and integrated switch assemblies upon request

MK vs MKC Series – What’s the Difference?

While both the MK and MKC series share the same core characteristics—such as aluminium housing, IP55 protection, permanent capacitor operation, and insulation class F—the MKC series offers enhanced installation flexibility thanks to its removable feet and side-reversible terminal box. This makes the MKC motors especially suitable for compact or custom-mounted configurations where space orientation matters.

Additionally, the MKC range includes frame sizes starting from IEC 56 and is manufactured and kept in stock not only in 2- and 4-pole versions—as is typical for single-phase motors—but also in 6-pole variants. By contrast, the MK series starts at IEC 71, features a natural unpainted aluminium finish, and is specially designed with higher starting torque, making it a more suitable choice for complex applications with increased torque demands.

RESOURCES