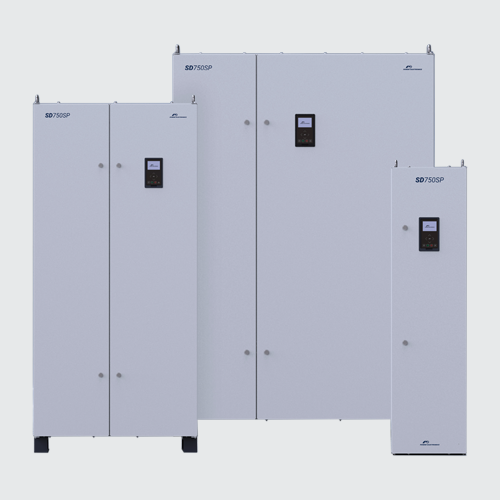

SD750SP

TECHNICAL DATA

Solar Pumping Solutions – SD750SP Series

Power Electronics is strongly committed to reducing the Levelized Cost of Water (LCoW) by delivering advanced energy-saving solutions. The synergy between our Industrial and Solar Divisions has resulted in the development of the SD750SP Solar Power series, a versatile and innovative approach to solar pumping.

Solar-Assisted Operation

The SD750SP can be connected simultaneously to both the mains (AC) and the PV field (DC). The AC input voltage determines the DC bus voltage of the SD750SP, which in turn sets the required DC string voltage. The maximum energy harvested at a fixed DC voltage is defined by the number of PV panels connected in series, allowing for flexible system design and optimization.

Self-Sufficient Solar Operation

In fully off-grid mode, the SD750SP operates exclusively from the PV field, generating the necessary power to start and drive the pump. The minimum required power depends on the hydraulic response of the complete pump and load system.

Customized for Solar and Hybrid Supply

The SD750SP is a customized version of the SD750 VSD, designed with an extended DC input range, making it suitable for AC, DC, or hybrid operation. It features enhanced firmware with integrated Maximum Power Point Tracking (MPPT) to optimize performance under varying solar conditions.

Optional Solar Kits and Engineering Support

Optional Solar Kits are available, including diodes, DC protections, disconnection devices, and filtering components, for a complete and safe solar pumping solution. Additionally, our engineering and consulting department offers full support for PV sizing and SD750SP selection, ensuring the best system configuration.

A fully integrated cabinet solution is also available, enabling easy installation and commissioning in a compact and efficient setup.