SMM 2024, Hamburg

NEWS

SMM 2024, Hamburg

Global Maritime Trade Fair

For four days—September 3 to 6, 2024—Hamburg became the heart of the global maritime industry, hosting the 31st edition of SMM, the world’s leading shipbuilding and marine equipment trade fair.

With over 2,200 exhibiting companies and more than 48,000 participants from 100+ countries, this year’s SMM transformed the exhibition halls into a thriving meeting point for industry leaders, innovators, and emerging players. The atmosphere was charged with energy as companies showcased technologies and solutions aimed at a greener and more digital maritime future.

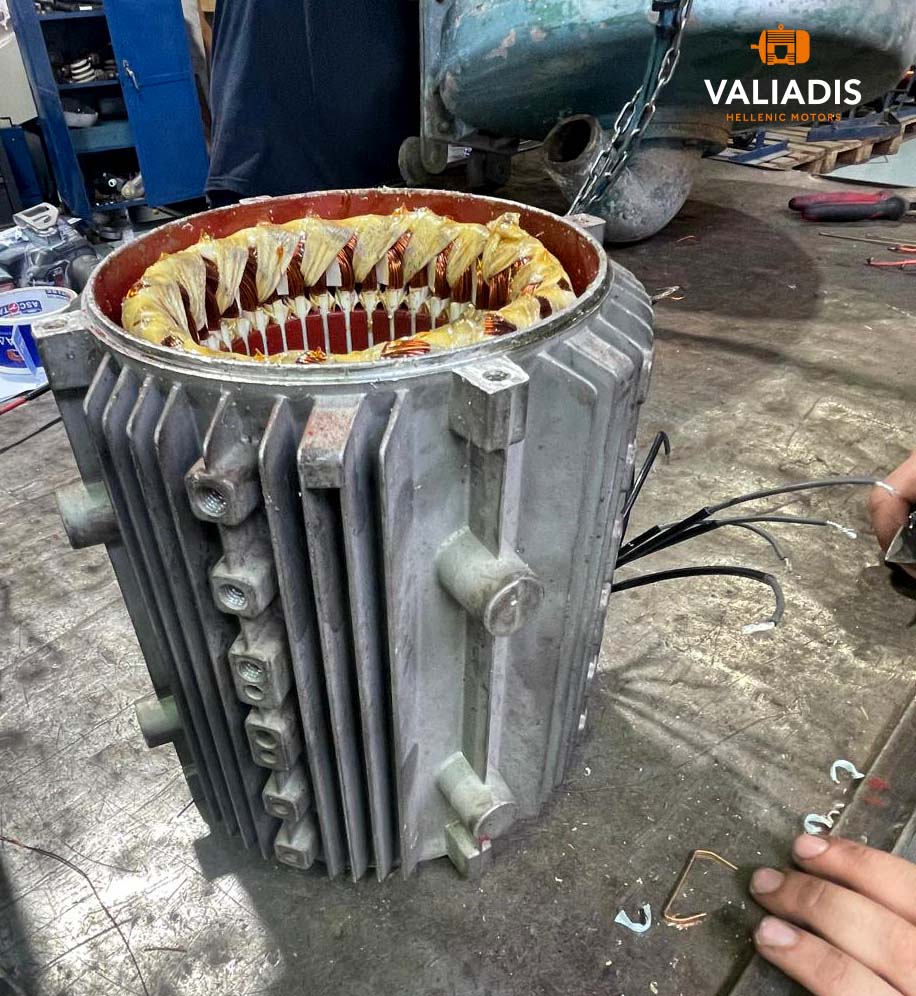

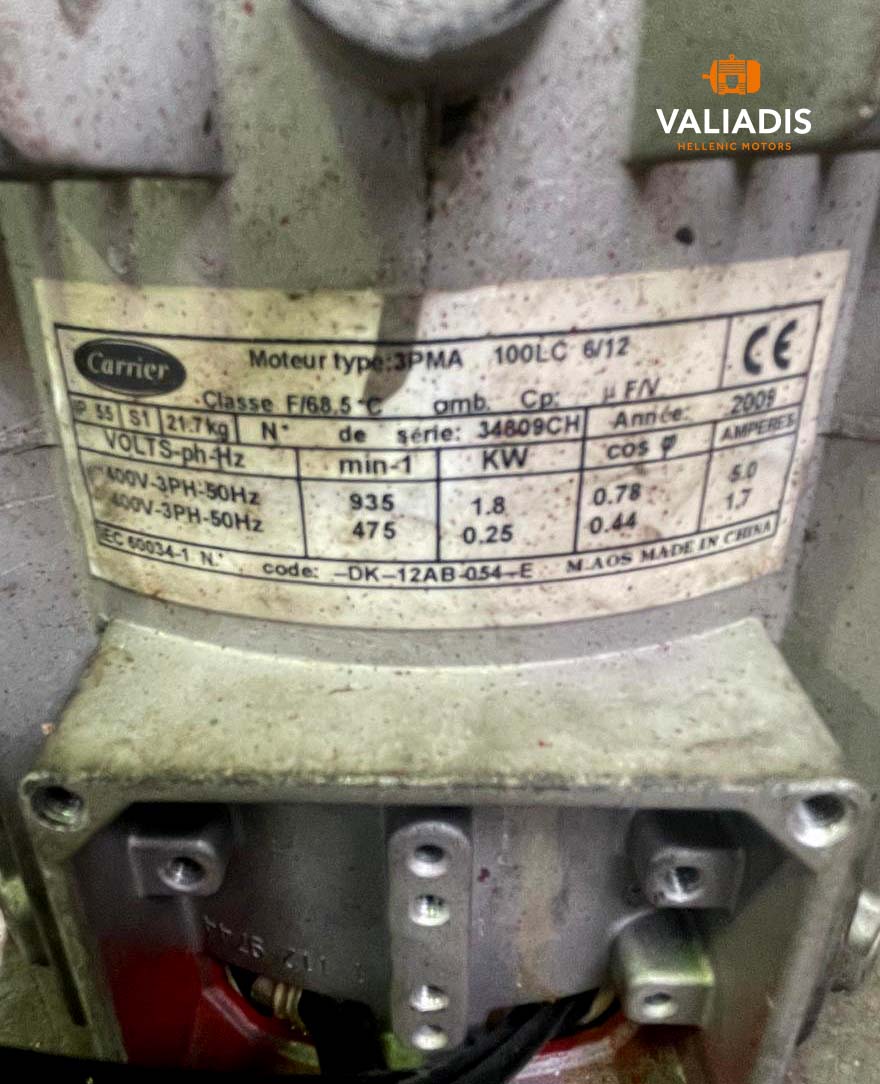

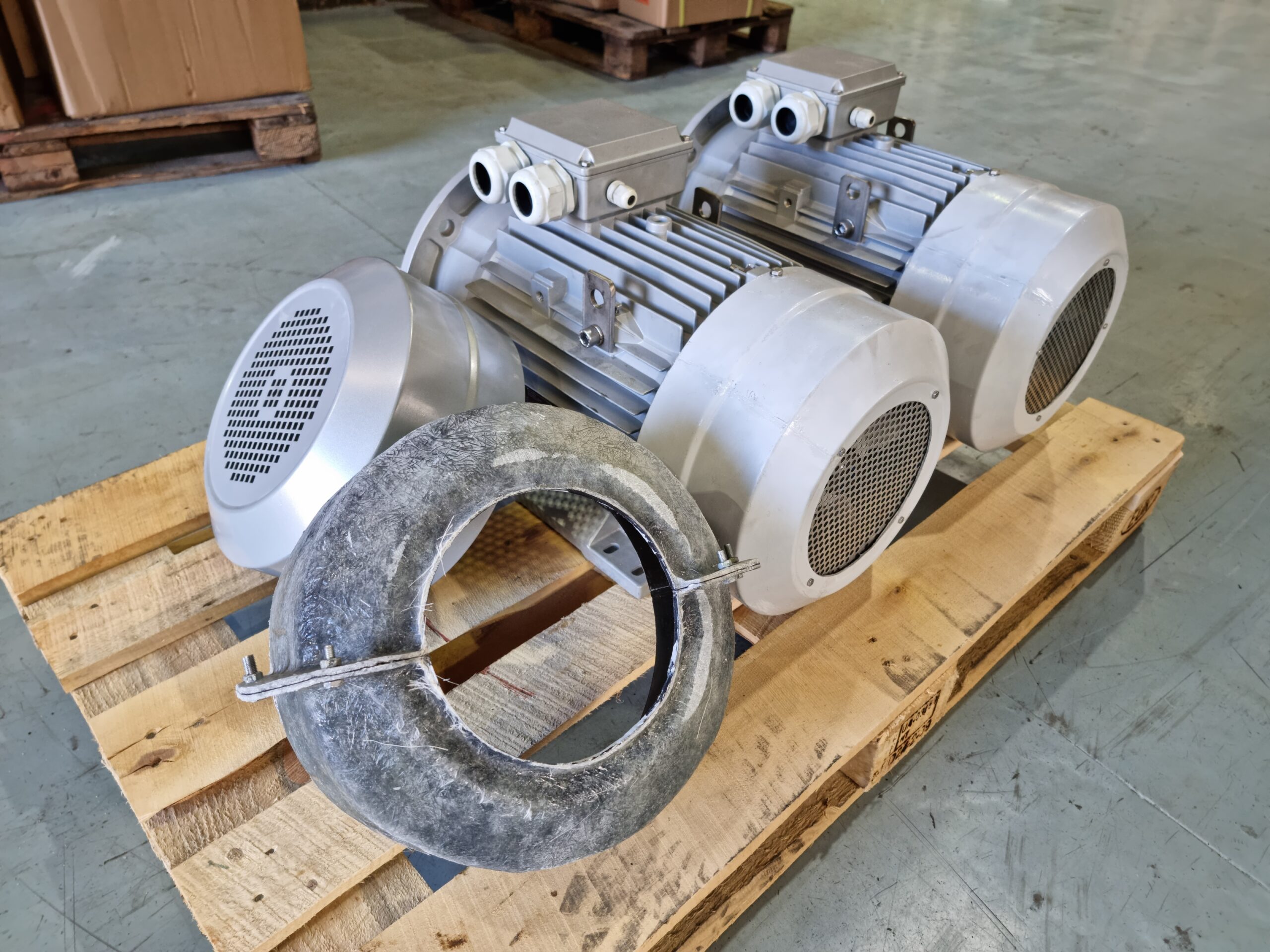

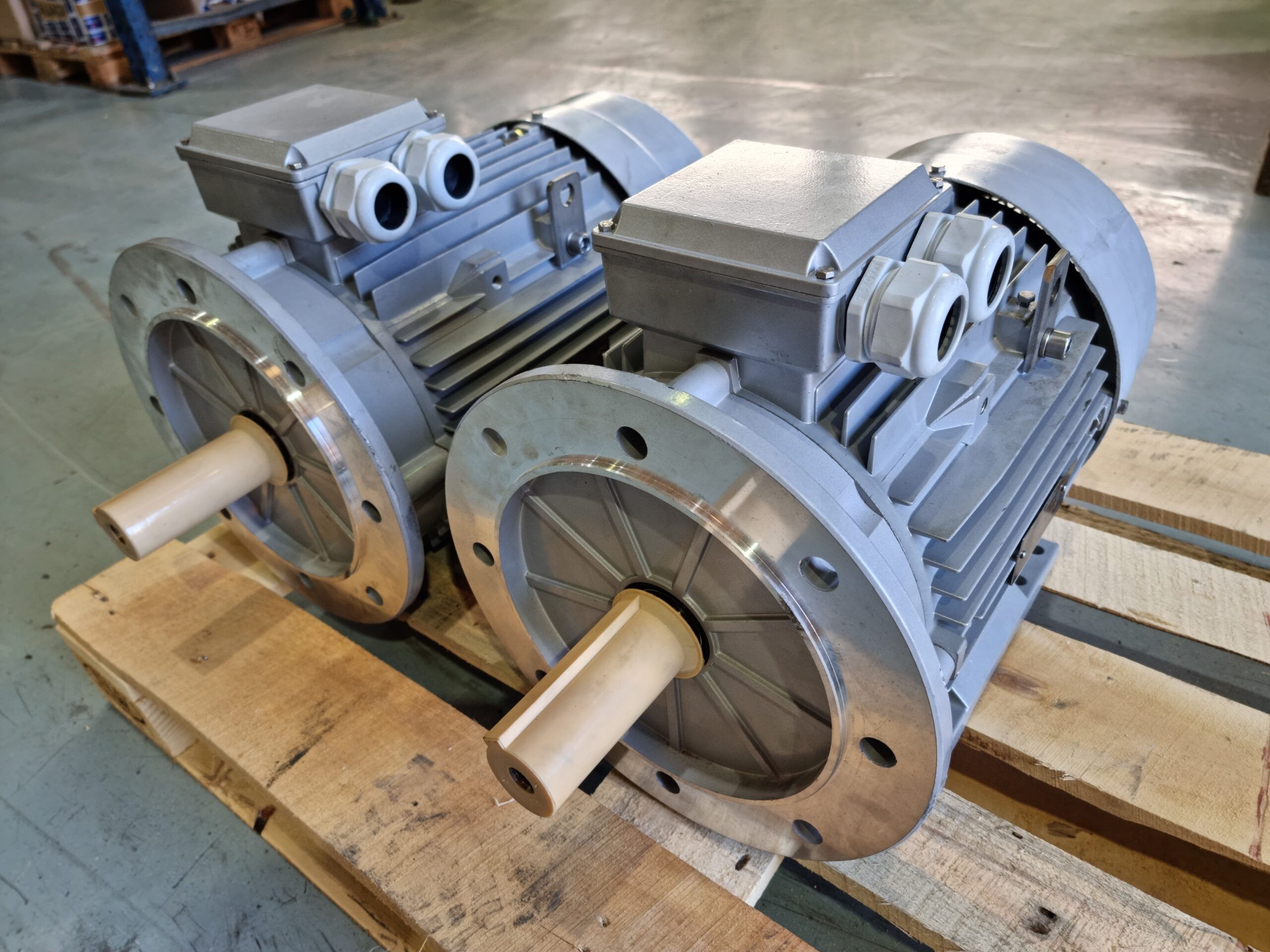

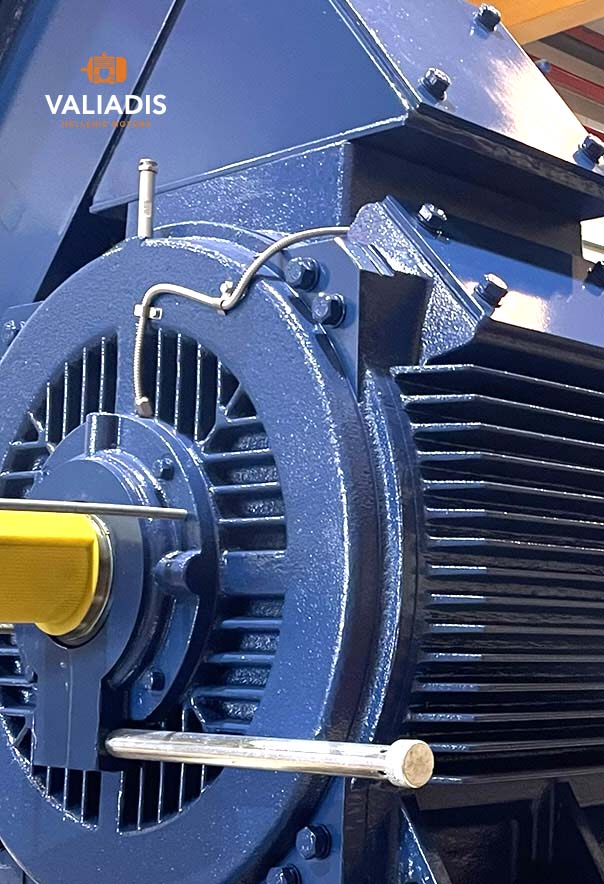

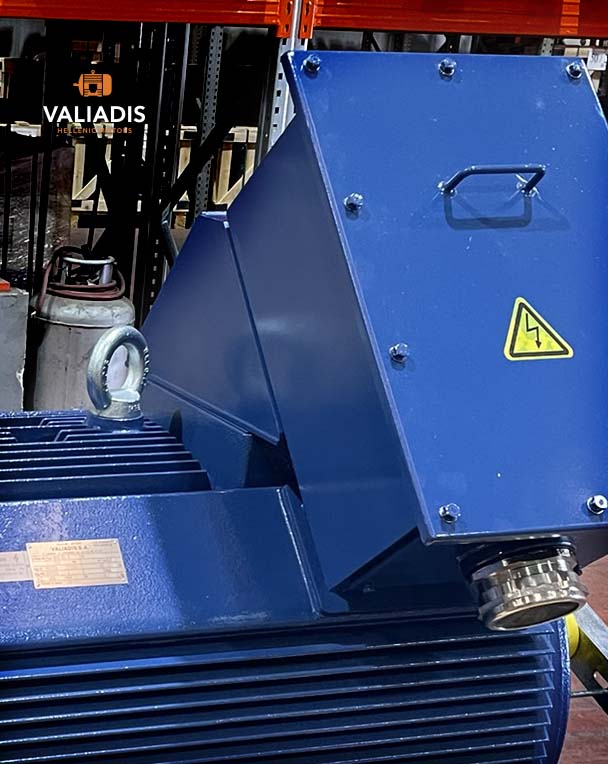

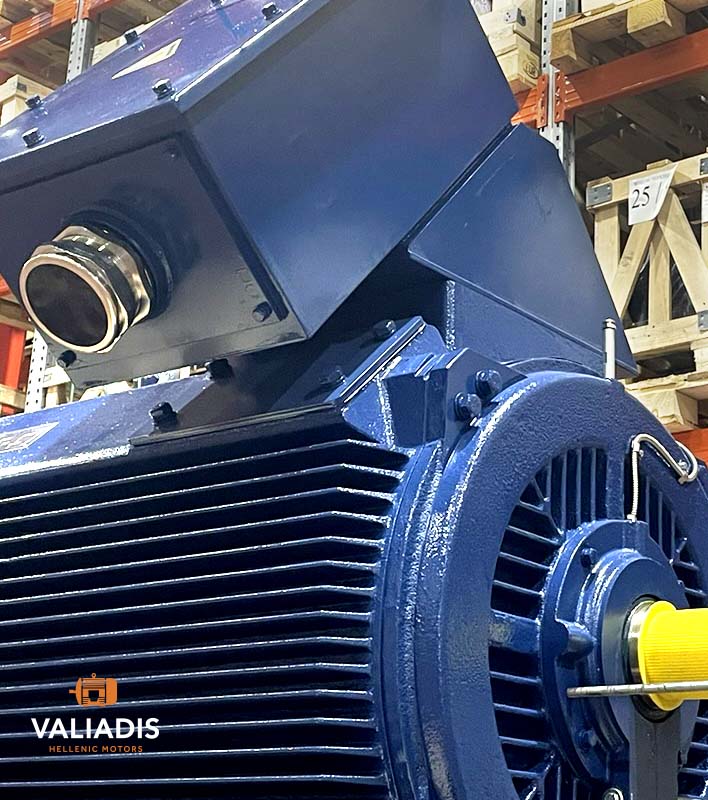

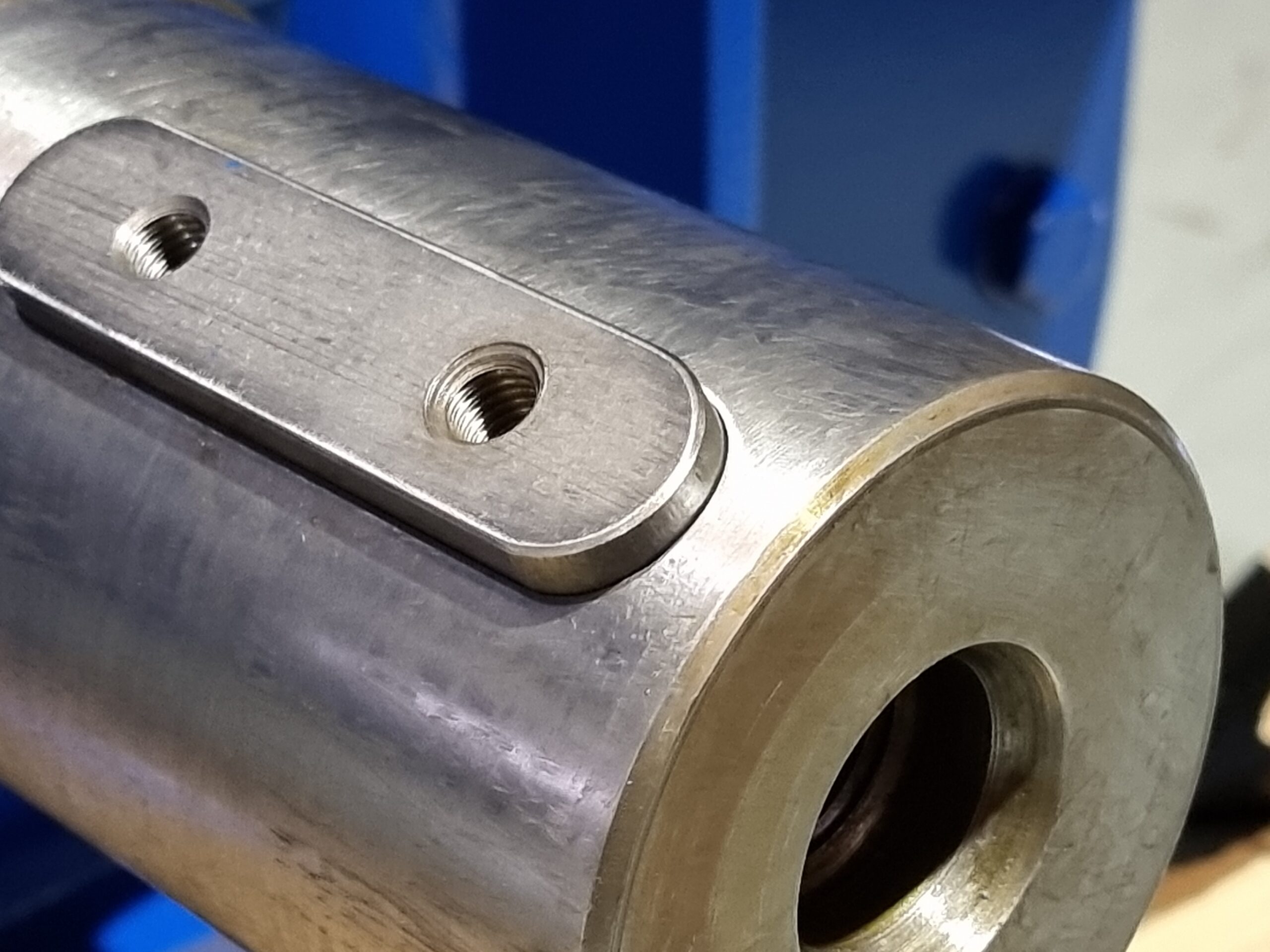

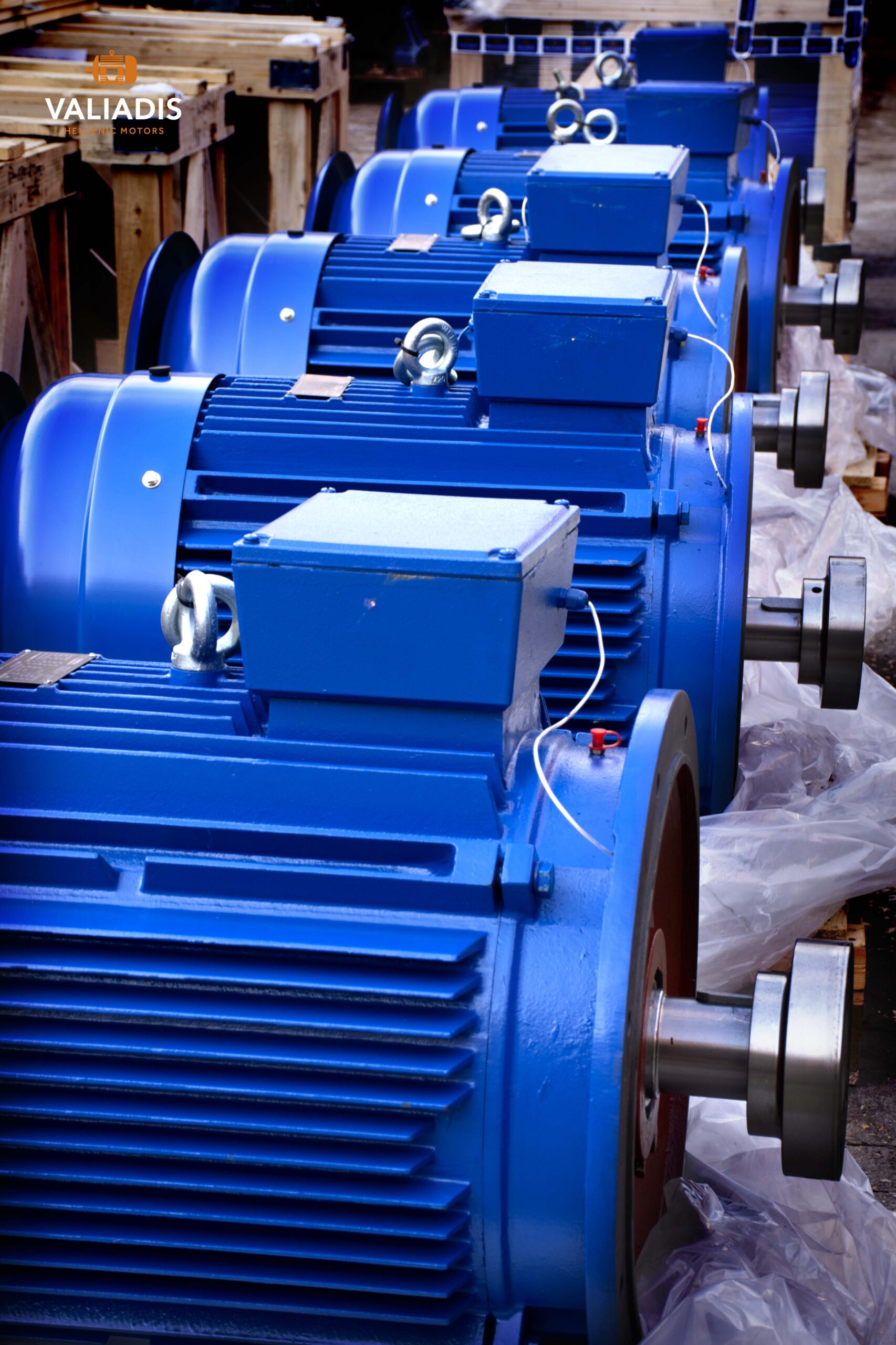

We were proud to take part once again, meeting partners, clients, and colleagues from around the world at Hall B6, Stand B6.614. From cutting-edge marine motors to custom engineering solutions, we contributed to the discussions shaping the future of global shipping.

Highlights included:

-

Five specialist conferences

-

Panels and networking sessions with top-level decision-makers

-

Focused dialogue on decarbonisation, digitalisation, recruiting, and maritime security

Looking ahead, we’re already preparing for the next edition:

SMM 2026, returning to Hamburg from September 1 to 4, 2026.

See you there!

-

IMG_8266-2

-

IMG_4377-2

-

3-IMG_4368-2

-

2-IMG_8297-2

-

1-IMG_8247-2

-

2

-

1