Europort 2023

NEWS

Europort 2023

The Maritime World, Together

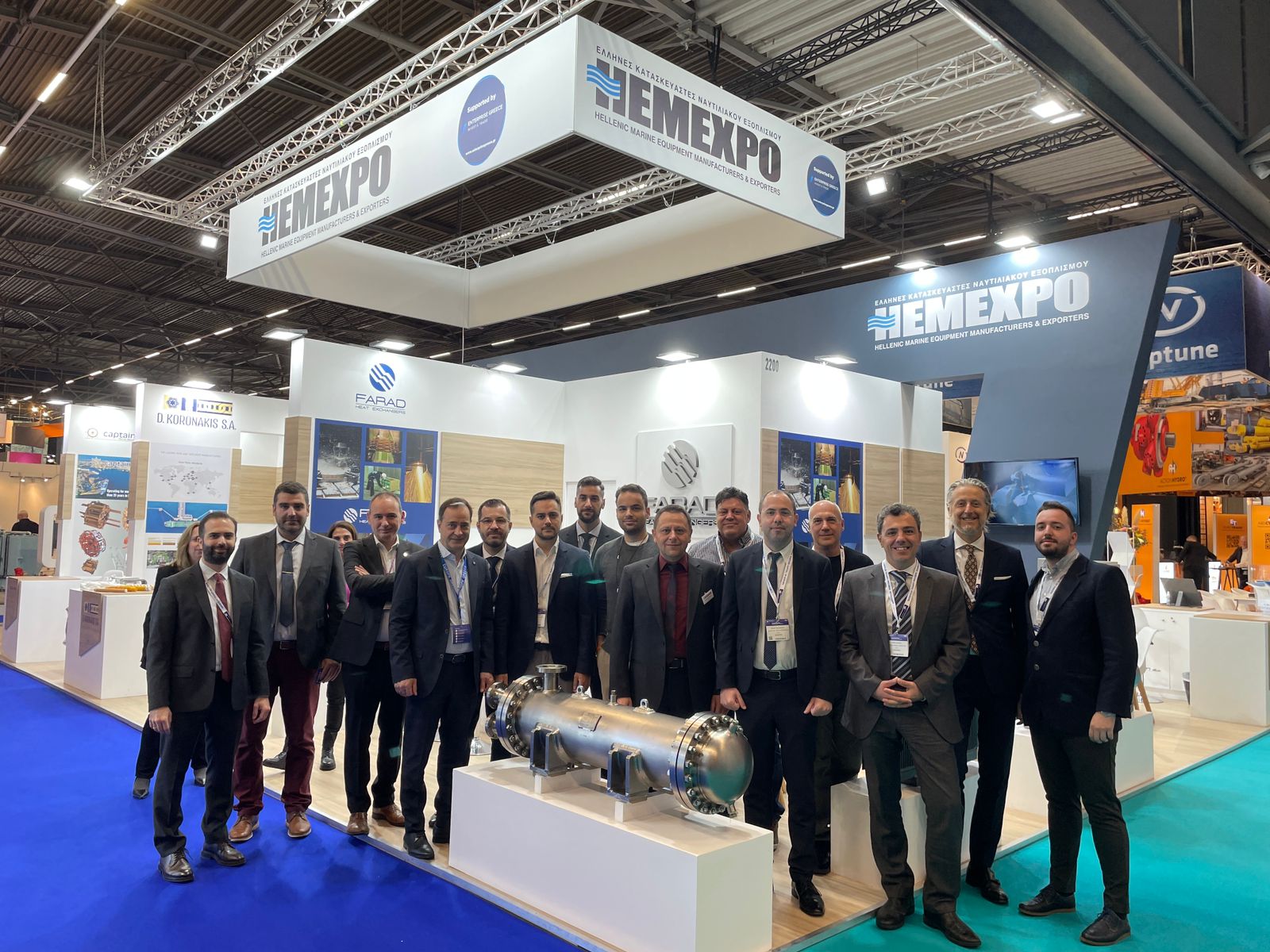

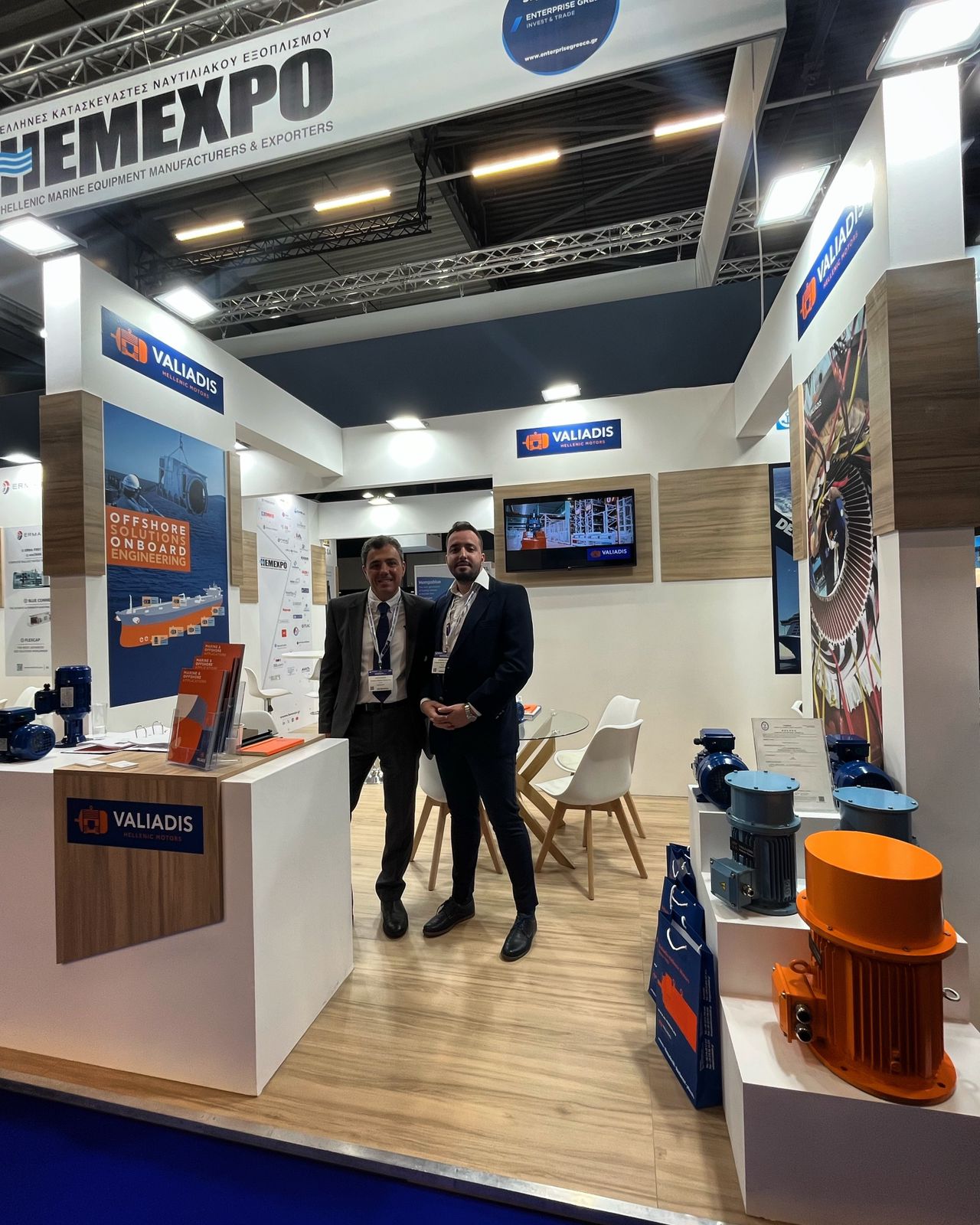

From November 7 to 10, 2023, we joined over 1,000 exhibitors and nearly 25,000 professionals at Europort, one of the world’s largest and most respected maritime exhibitions, held in Rotterdam Ahoy.

Renowned for its focus on special-purpose vessels, maritime transition, and high-tech innovation, Europort 2023 once again proved to be a vital meeting ground for the global shipping industry. With professionals attending from over 100 countries, the exhibition emphasized the need for in-person connection and collaboration—something increasingly valuable in our digital world.

We were proud to take part in this dynamic environment at Stand No. 2208, showcasing our expertise in marine motor technologies and our commitment to powering forward-looking solutions across the maritime sector. Europort continues to be a hub for technological exchange, partnerships, and industry foresight—and we were excited to contribute to that momentum.

As always, thank you to everyone who visited us in Rotterdam. We’re already looking ahead to future editions.

-

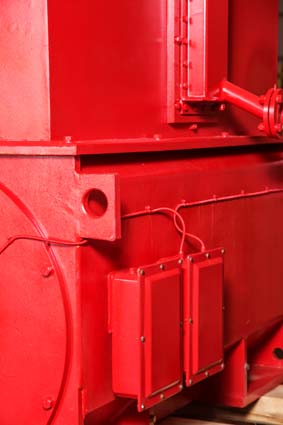

WhatsApp Image 2023-11-10 at 17.57.19_73783686

-

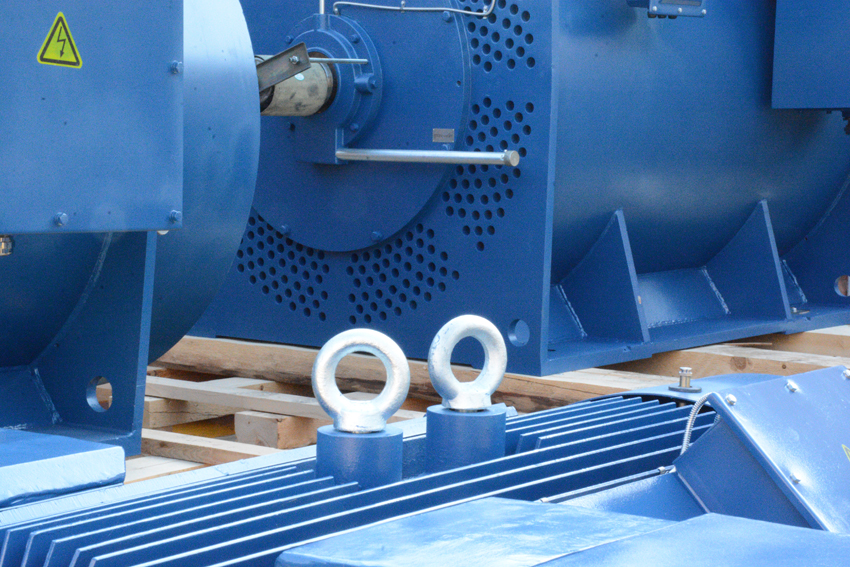

WhatsApp Image 2023-11-08 at 14.02.43_9351a7dc

-

WhatsApp Image 2023-11-08 at 13.57.04_595d4c27

-

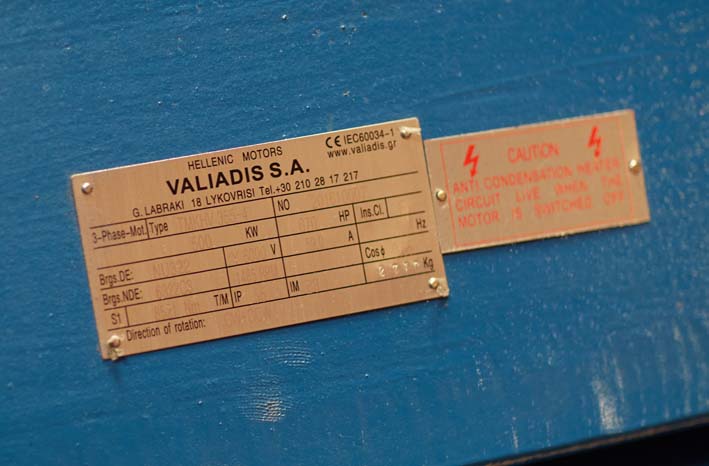

WhatsApp Image 2023-11-08 at 13.56.56_d8377722